Kipardo 19 20 21 22 inch factory custom wholesale luxury alloy rims aluminum 4×4 offroad wheels

Product Description

MODEL NO:80295

| Size | 19/20/21/22 inch | Material | Aluminum Alloy |

|---|---|---|---|

| PCD | 5x112-120 | MOQ | 80PCS |

| Standard Carton | Brown Carton/White Carton | Warranty | 3 Years |

| High Light | Factory wholesale customized aluminum Alloy offroad wheels | ||

Production process

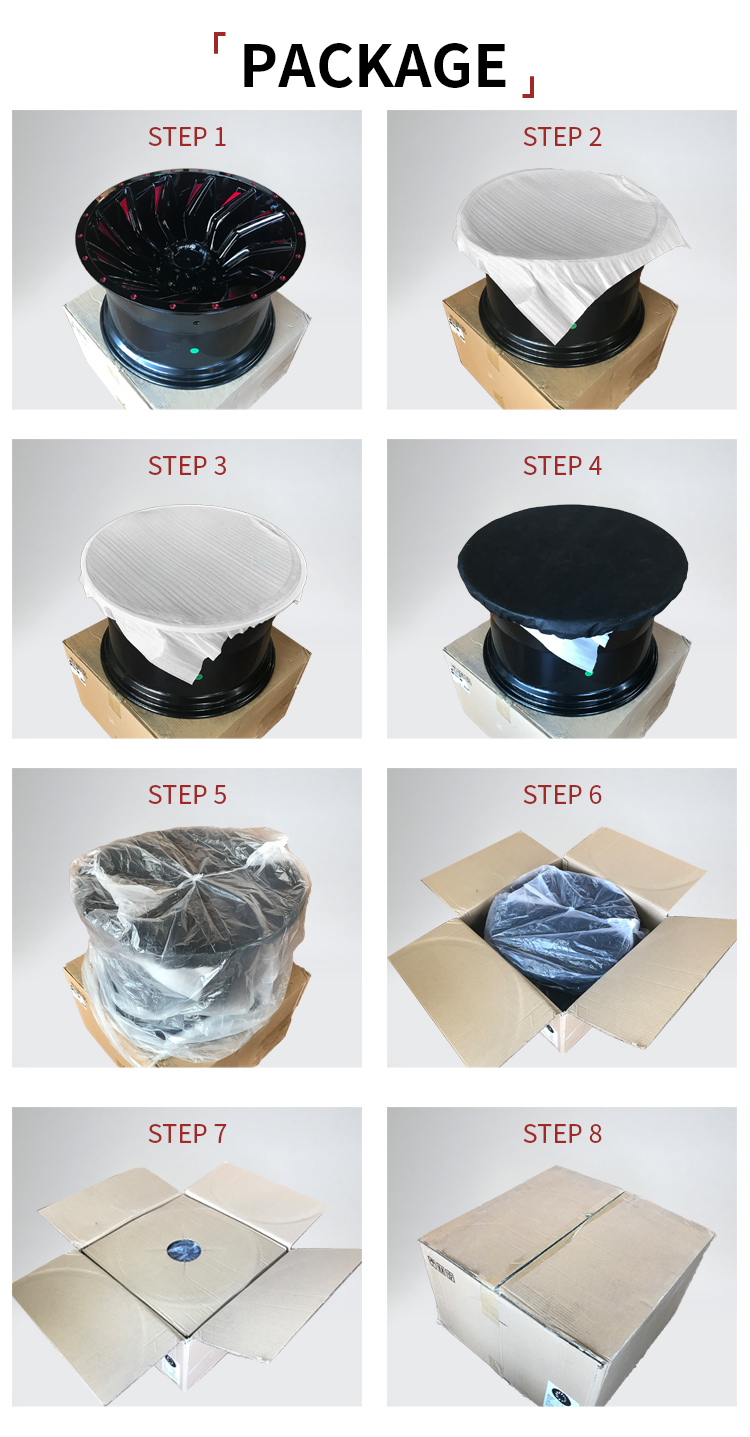

PACKAGE

Our exhibition

Special Service

1. We provide timely per-sale and after-sale service: Before the sample/mass production order placed, all details will be checked and confirmed with customers; We can accept sample order for testing first. Also we have a free sample policy if you place an order to us

2. We provide LOGO customizing (Milled Letters and Word) on wheels;

3. Center caps and Carton LOGO customizing;

4. Wheel's finishing can be your requested.

5. We can do forged, Flow forming and Lower pressure

FAQ

1.Q: How about quality guarantee of your wheels?

A:1) Material Purchase Control Our Material are imported from Malaysia, Thailand ect. Those country specializing in better rubber.

2) Advanced production equipment, including German Krupp mixer, Netherlands VMI tire building machine.

3) all semi-finished tires are inspected 100%, qualified rate is almost 100%. This is seldom in China.

4)There are 5 times inspection for each tyre, including appearance test,X-ray test, dynamic test and so on.

2. Q: Terms of payment

FOB,30%TT deposit, 70% balance before shipping

C&F, 30% TT deposit, the balance should be paid against copy of B/L within 10 days.

By irrevocable LC at sight.

Do you kown

Forging wheel hub is a kind of manufacturing technology commonly used in current automotive manufacturing industry. The process is mainly completed by the stamping of hot blank by the forging machine on the die of the brake drum, and the blank is forced to be formed under the pressure.

The forging wheel hub has a high strength, good performance, and great rigidity. As a result, the deformation of the wheel hub will also be reduced in the process of driving. In addition, compared with the ordinary stamping wheel hub, the process of forging wheel hub has high overall productivity, even for the complex shape of some wheel hubs. The production efficiency can still be achieved can be increased with the support of forging machine.

The forging wheel hub is mainly used in the rear axle of large trucks and small and medium buses. According to the corresponding size and pattern position, various forging wheel hub and brake drums can be manufactured. Moreover, forging process is suitable to produce wheel hub with complex shapes and large size, which can meet the demands of various vehicles.

Therefore, forging wheel hub is the preferred option for automotive production industry. It can not only meet the various requirements of vehicle types, but also reduce the deformation of the wheel hub in the process of driving, thus increasing the service life and enhancing the driving safety of the vehicles.